Complete Flakes

Measures on 1063 complete obsidian flakes from the obsidian workshop test unit provides evidence of changing activities through time that support the observations made on cores and retouched artifacts. Flakes will be examined first through the mean values on their numeric attributes.

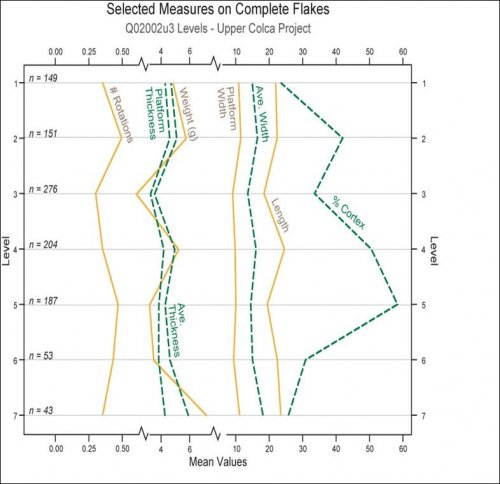

Figure 7-24. Q02-2u3: Graph showing means of measures on complete obsidian flakes.

The mean values of flake measures length, average width, average thickness, weight, platform width, platform thickness, percentage of dorsal cortex, and count of rotations were presented. The average width and average thickness variables were calculated by averaging the Proximal, Medial, and Distal measures for Width and Thickness on each flake.

|

Measure |

df |

F |

Sigif. |

|

Length (mm) |

6 |

9.392 |

.000*** |

|

WidthAve (mm) |

6 |

7.290 |

.000*** |

|

ThickAve (mm) |

6 |

9.431 |

.000*** |

|

PlatWidth (mm) |

6 |

2.344 |

.030* |

|

PlatThickness (mm) |

6 |

2.358 |

.029* |

|

Weight (g) |

6 |

7.707 |

.000*** |

|

% Cortex |

6 |

18.819 |

.000*** |

|

# Rotations |

6 |

2.914 |

.008*** |

Table 7-21. Q02-2u3: ANOVA on measures from complete flakes.

The observed differences in means are extremely significant ( p? .001) except for the means of platform width and platform thickness, which are merely significant ( p< .05). While mean values across levels are highly subject to skewing due to overrepresentation by the numerous small flake categories, the data in Figure 7-24 demonstrate that the large sizes associated with level 4 cores discussed previously are repeated in the flakes from level 4.

In Figure 7-24, the percent cortex variable shows a notable spike in level 5 but this variable should be considered in conjunction with the weight variable because by weight and size these highly cortical flakes are relatively small. Looking at the percent cortex in level 7, in contrast, one can see that there is little cortex and a mean weight of 8 grams indicating relative abundance and relatively wasteful reduction at the workshop. These large level 7 flakes appear to have come from large cores because they are comparably heavy, wide, and thick, and the flakes are not very cortical. This changes rapidly in level 6 as mean weight goes down despite a slight increase in corticality. The number of rotations similarly points to more efficient decortication in level 5 with thinner, shorter flakes that are relatively cortical. Level 3 rotations are low, although this is perhaps a product of the small overall size of these flakes hence rotations are less visible on the smaller surface.

Platform characteristics are important determinants of flake morphology (Dibble 1997;Dibble and Pelcin 1995;Shott, et al. 2000) and can point to changing reduction strategies because platform attributes directly convey changes in knapping decisions in terms of point and angle of force. Platform characteristics show intriguing relationships with other flake characteristics, but the patterns are difficult to explore in the aggregate. As with multivariate analysis in cores above, the patterns discussed in flake morphology in the workshop test unit can be further explored using cluster analysis.

Cluster analysis on Complete Flakes

Cluster analysis of flakes from the Q02-2u3 pit elicits groupings from the numerical variables taken on complete flakes, and provides a way of reducing the dimensionality of the flake morphology dataset without the limitations of typological classification of flakes. Thirteen numerical measures were gathered on complete flakes and when these thirteen were included in the cluster analysis it was apparent that ten of the measures were related variables because they were measures that reflect overall flake size. As a consequence, the clustering solutions that emerged, regardless of the clustering method employed, tended to reflect the size groupings of smallest, medium, and largest measures in most attributes. A reduction of dimensionality was needed to collapse these correlated size measures into fewer variables so that a second order of variability in attributes that were not size dependent could emerge. Dimensionality can be reduced by conducting a Principal Components Analysis on the data prior to clustering, and then clustering the components with Eigenvalues of approximately 1 or higher.

Clustering the results of Principal Components Analysis (PCA) has precedence in archaeology going back to the 1970s (Ahler 1973;Redman 1973). In this study, the thirteen variables were first reduced to four PCA components and, subsequently, a Ward's Method clustering derived a 3 cluster solution from these 4 components. The numerical measures on complete flakes submitted to Principal Components Analysis include: weight, length, proximal width, medial width, distal width, proximal thickness, medial thickness, distal thickness, platform width, platform thickness, platform angle, percent cortex, and number of rotations. Mean values were substituted for empty values in the PCA. In this study, four PCA components with eigenvalues greater than 0.988 were clustered accounting for 75% of the variability in the dataset. Next, these four components were entered into a cluster analysis.

A variety of hierarchical clustering methods were explored and the most appropriate clustering solution appeared to be Ward's Method where three clusters were derived with a minimum of internal variance. In Ward's Method, cluster membership is assessed by calculating the total sum of squared deviations from the mean of the cluster. By maintaining the smallest possible values for the error sum of squares then intracluster variance is minimized and intercluster variance is maximized.

|

Function |

||

| 1 |

2 |

|

|

Plat Thickness |

.571* |

.094 |

|

Plat Width |

.546* |

.079 |

|

Width Prox |

.528* |

.202 |

|

Plat Angle |

-.493* |

.252 |

|

Thick Prox |

.411* |

.297 |

|

% Cortex |

.297 |

.705* |

|

Weight (g) |

.208 |

.452* |

|

Thick Med |

.324 |

.451* |

|

Thick Dist |

.153 |

.424* |

|

Length |

.164 |

.394* |

|

Width Med |

.305 |

.345* |

|

Width Dist |

.107 |

.309* |

|

Rotations |

.006 |

-.060* |

|

* Largest absolute correlation between each variable and any discriminant function |

||

Table 7-22. Canonical Discriminant Function Structure Matrix in order of size of correlation.

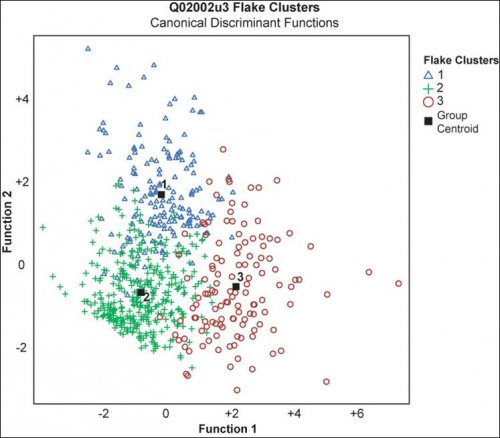

Figure 7-25. Canonical discriminant chart for complete flake clusters from Q02-2u3.

In Table 7-22, the contribution of each of the different measures taken on flakes to the two functions that emerge from cluster analysis are shown. Function 1 responds to platform characteristics, the morphology of the proximal parts of each flake, and flakes with tapering widths. Function 2 primarily responds to the variables that reflect the overall size, cortex, and rotations measures of each flake.

This clustering solution brings out the variability by excavation level among flakes in Q02-2u3 that were discussed above. Broadly speaking, the clusters discriminate large cortical flakes from small, non-cortical flakes, but a third group, differentiated primarily by its platform characteristics, also emerged from the analysis.

|

Characteristics of Three Flake Clusters from Q02-2-u3 |

|||

|

F1(n=265) |

F2(n=668) |

F3(n=130) |

|

|

Size and Platform |

Longest flake class, and slightly heavier than F3 class. Includes the greatest size variability. |

Smallest flakeswith the smallest platforms and moderate platform angle. |

Moderately large flakes with very large platformsand very acute platform angles. Tapering significantly proximal to the distal. Slight tendency for faceting as a form of platform preparation. |

|

Cortex, Rotations, Terminations |

Significantly more cortex than other clusters but only slightly fewer rotations. Many plunge terminations, few hinge. |

Significantly little cortex. Few rotations. The most hinge terminations, fewest plunge. |

Moderate amounts of cortex, slightly more rotated than other clusters. |

|

Ob1 vs Ob2 |

Some Ob2. (n=14), 5.3% |

Few Ob2. (n=20), 3.0% |

Few Ob2.(n=5), 3.8%. |

|

Comments |

Largest flake class. These flakes are conceivably serving as blanks. |

Smallest class of flakes and advanced reduction flakes. |

Possibly corner removal flakes on tabular obsidian nodules. |

Table 7-23. Q02-2-u3: characteristics of 3 clusters of flakes based on numerical attributes.

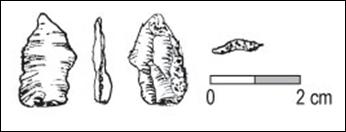

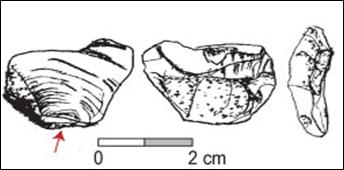

Figure 7-26. An example of a flake from the F1 cluster [L03-162.21].

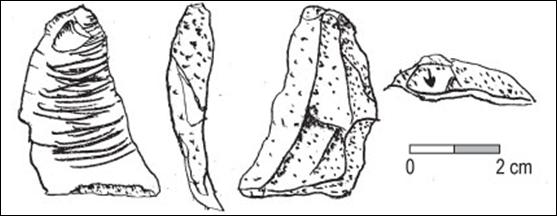

Figure 7-27. An example of a flake from the F2 cluster [L03-162.118].

Figure 7-28. An example of a flake from the F3 cluster [L03-162.66].

These clusters capture much of the variability present in the flakes from Q02-2u3. Patterns among nominal attributes of these clusters are also worth examining. Non-numerical attributes could not be submitted to the PCA and clustering functions directly because only quantitative measures can be used with that procedure. Nominal attributes, such as flake termination, must be addressed using analyses measures of association such as Standard residuals and Cramer's V.

|

Flake Cluster |

Termination |

||||

|

Feather |

Hinge |

Plunge |

Step |

||

|

1 |

No. |

166 |

20 |

62 |

13 |

|

Std. Residual |

-.3 |

-4.0* |

5.0* |

1.0 |

|

|

2 |

No. |

431 |

154 |

59 |

22 |

|

Std. Residual |

-.2 |

3.0* |

-2.8* |

-.6 |

|

|

3 |

No. |

93 |

18 |

14 |

5 |

|

Std. Residual |

.9 |

-1.2 |

-.6 |

.0 |

|

Table 7-24. Q02-2u3:c2showing types of terminations by flake cluster. On the whole, these relationships are not very strong (Cramer's V = .171).

In Table 7-24 standard residuals point to significant differences in the cluster 1 and 2 proportions of hinge and plunge terminations. In this table, a significant difference exists where ever the standard residual exceeds 1.96. However, on the whole, the table relationships are not very strong because the Cramer's V for the table is just 0.171. The proportions of hinge and plunge terminations are notably different between F1 and F2. The high number of plunges in F1 might be explained by these flakes serving as decortication flakes where plunging terminations can serve to clear off the bottom of the core to improve the chances of achieving feather terminations in subsequent blows. As a core maintenance strategy, plunging terminations can improve subsequent flaking events by increasing the striking angle. Furthermore, when the end of the core is non-cortical it increases the chance of feather terminations.

Other platform attributes of these flake clusters include an unusually high incidence of faceting on the platforms of F3 flakes. This kind of platform preparation is sometimes used to remove cortex or inconsistencies from the platform area. Furthermore, ac2table showed that Platform Angle, the distinctively low attribute of F3 flakes, is the variable with strongest association with the three cluster classification (Cramer's V = .457).

Interpretation with an Investigation of Flake clusters by Excavation Level

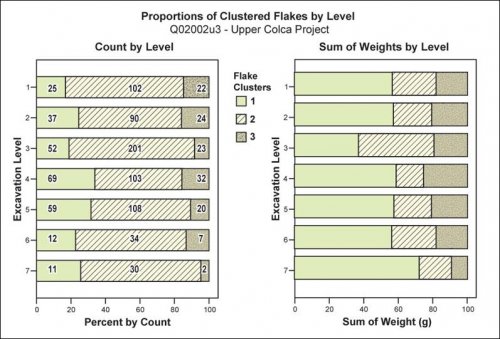

Investigating the proportions of these flake clusters by excavation level provides insight into the changing activities at the Maymeja workshop. A graph showing the proportions of these clusters by level will be shown and discussed in detail beginning with the oldest strata, the Terminal Archaic level 7 (2880-2650 BCE).

Figure 7-29. Graph showing Flake clusters by excavation level.

Level 7- Basal level

A high proportion of F1 flakes by weight was in keeping with expectations concerning early use of the workshop area. Early reduction of widely available large cores resulted in a large number of F1 flakes. The F3 flakes in this level had relatively acute platform angles.

Level 6- Large Platformed Flakes (F3)

An increase in F3 by count and weight in level 6 that persisted through later levels in the unit hints at a change in reduction strategy that produced these large platformed flakes. The defining characteristics of these flakes, are large platforms with very low dorsal platform angles, and these are very pronounced in this level within the F3 group. In reviewing the core clusters by level from Figure 7-22, there are few cores in this level and a relative prevalence of small cores, suggesting a decrease in availability of the large cores found in other levels. The production system that was dominant in level 7 had perhaps been altered by level 6 for lack of raw material in large nodules.

Level 5 -Core export level.

This level maintained roughly the same proportions of F1, F2, and F3 flakes, but the overall flake counts were much higher. In other words, a pattern that began in level 6 developed into full-fledged production strategy in level 5 because the proportions suggest that similar activities were being preformed but with higher production rates. The F2 flakes had significantly smaller platform thicknesses, a characteristic that fluctuated greatly between levels. The F2 flakes also had more rotations and they had much more cortex than F2 flakes did in higher, later levels. This suggests that smaller cores were being decorticated in level 5. Revisiting the core proportions from Figure 7-22, it is notable that large C3 cores dominated the assemblage of discarded cores in this level, despite the evidence from the flakes that small cores were in use. Hence, it appears that certain cores were decorticated and exported and therefore such cores appear in reduced frequency in this level.

A notable increase in the number of bifacially retouched flakes and broken bifaces is apparent in level 5, indicating that a pattern of some more advanced reduction activities was underway during these levels. There is also a slightly higher representation of Ob2 material among F3 flakes in this level.

Level 4 -Large flake blank production level

In general, production patterns first witnessed in level 5 continued at a higher rate in level 4. A14C sample from this level had a radiocarbon date from the Early/Middle Formative transition (1500-1320 BCE). The large F1 flakes had significantly more rotations while F2 flakes had fewer rotations. F2 flakes also had thicker platforms in this level, particularly contrasting with thin platforms on F2 flakes in the surrounding levels 3 and 5. All cores had significantly more rotations than in preceding and succeeding levels (see Figure 7-23), and this was particularly true of the tabular C2 core cluster. There was a slight increase in C2 cores in this level. These data indicate that further rotations were being applied, and that large tabular C2 cores, which were heavily decorticated and thus must have been extremely large to start with, were being discarded in abundance in this level. The level 4 excavation strata was also unusually thick (13.9 cm), therefore proportions are comparable to other levels while the actual count are not directly comparable. One significant difference between level 5 and level 4 is the presence of large cortical flakes in level 4, as shown in Figure 7-23.

Level 3 - Advanced reduction

Level 3 was distinguished because it contained a far greater number of small flakes and cores than did previous and subsequent levels. It was mentioned above that evidence of advanced reduction in level 3 included the discard of 13 broken bifaces yet only 2 retouched flakes were discarded. The many small flakes in this excavation level resulted in much higher artifact densities. Among the F1 flakes the lengths and weights were lower, while among F2 flakes the lengths were significantly longer, and among the F3 flakes weight dropped significantly. Thus, flakes in all 3 clusters shifted towards the smaller ends of their size categories. There were twice as many F2 flakes in level 3 than in previous levels, and they had low platform thickness, few rotations, and had significantly less cortex than did previous levels.

Cores in level 3 primarily consisted of large C3 cores that essentially replaced the C2 cores in this level. The lack of C2 cores suggests that the cores were either being further knapped, or they were being transported away through export during this occupation level.

The evidence from level 3 is consistent with workshop activities that had shifted from initial reduction to more advanced stages of reduction. The absence of large cortical flakes and large tabular C2 cores suggests that the investment in procurement that was supplying the cores to the workshop had changed,and perhaps excavating at the quarry q02-2 had ceased. As this is a workshop area with a long history of use, scavenging could have continued for many years as relatively large cores and flakes were surely extant in the workshop area. It appears that the system was essentially well-stocked in the beginning of level 3 but it appears that by the end of level 3 the easily available, knappable obsidian was relatively depleted.

Level 2 - Returning to production

Cores and flakes in level 2 return to a larger size scale. There were relatively few broken bifaces compared to retouched flakes. There are additional rotations on both F1 and F2 flakes, and F2 flakes had very little cortex and high platform thickness values. A return to quarrying at the q02-2 quarry is one possible explanation for the higher availability of material in these levels. In level 1, the F1 flakes are significantly rotated and some of the obsidian has notable quantities of irregular cortex.